A Massive Investment Approval

Thailand has taken a significant step toward becoming a global electronics manufacturing hub with the approval of a 65 billion baht ($2.08 billion) investment from a joint venture led by Taiwan’s Zhen Ding Technology (ZDT). The Board of Investment (BOI) granted approval for four consecutive printed circuit board (PCB) manufacturing projects in Prachin Buri province, marking one of Thailand’s largest investments in advanced electronics manufacturing.

The joint venture, operating as Peng Shen Technology (Thailand) Co., Ltd., brings together ZDT—the world’s largest PCB manufacturer—and Thailand’s Saha Pathana Inter-Holding Plc. This collaboration represents a strategic move by Thailand to attract high-value foreign direct investment while positioning itself as a critical player in the global electronics supply chain.

Narit Therdsteerasukdi, Secretary-General of the Board of Investment, emphasized the significance of this development for Thailand’s industrial landscape. He noted that the investment underscores Thailand’s growing importance in the global electronics industry amid shifting supply chains and increasing demand for advanced electronic components.

Zhen Ding Technology: A Global Electronics Giant

Zhen Ding Technology Holding Limited has ranked as the world’s largest PCB manufacturer continuously since 2017, establishing itself as a key player in the global electronics supply chain. The company generates annual revenue exceeding 180 billion baht and employs over 48,000 people worldwide across its operations in Taiwan, China, and now Thailand.

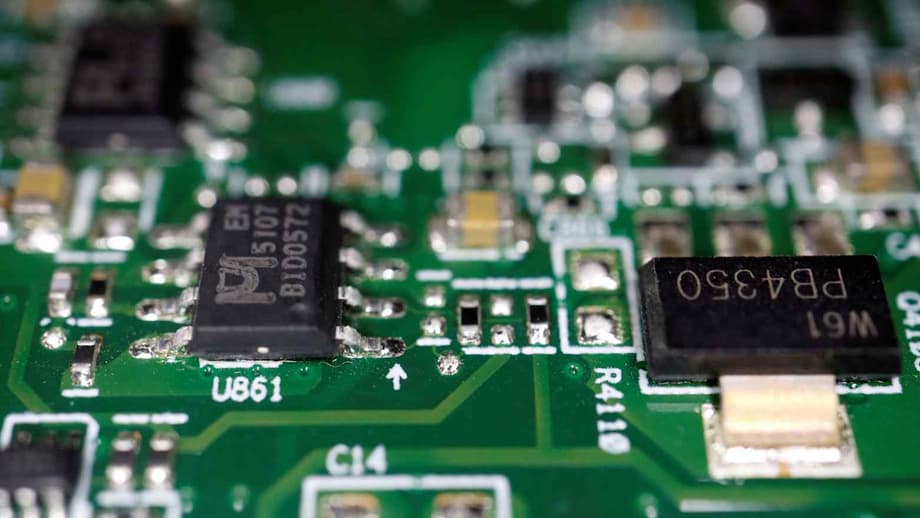

PCBs serve as the foundation of almost all electronic devices, acting as the critical interconnectivity platform that enables electronic components to communicate and function together. From smartphones and laptops to medical devices, telecommunications equipment, and energy infrastructure, PCBs are ubiquitous in modern technology. The complexity and quality of PCBs directly impact the performance, reliability, and capabilities of the final electronic products.

ZDT’s expertise spans advanced PCB technologies including multilayer PCBs, flexible PCBs, substrate-like PCBs, and high-density interconnect (HDI) PCBs. These sophisticated components are essential for modern electronics requiring high processing performance, such as 5G smartphones, artificial intelligence (AI) servers, data centers, electric vehicles, and other advanced electronic devices.

The company operates five major manufacturing campuses across Taiwan and China, with over 20 sales offices providing real-time business and technical services globally. The Thailand facility represents ZDT’s first and only manufacturing base outside its traditional territories, highlighting the strategic importance the company places on this expansion.

The Joint Venture and Project Details

The joint venture between ZDT and Saha Pathana Inter-Holding has developed a comprehensive investment strategy spanning multiple phases. The first project received approval in 2023 and began commercial production in September 2025. Following this successful launch, the company submitted applications for three additional expansion projects, which have now received BOI approval.

Combined, the four projects represent a total investment exceeding 65 billion baht, with the facility located in Prachin Buri province. The manufacturing complex will focus on producing high-complexity PCBs aimed at export markets worldwide, reinforcing Thailand’s position as a global manufacturing base for advanced electronics.

The investment is expected to generate substantial employment opportunities, creating jobs for more than 5,600 Thai workers. These positions will range from manufacturing roles to technical and engineering positions, contributing to skill development and knowledge transfer within the Thai workforce.

ZDT aims to make Thailand a manufacturing base for highly complex PCBs that serve demanding applications in AI servers, communications infrastructure, and optical modules. The first phase of the project includes the construction of one factory with production lines for SLP (substrate-like PCB), thick HDI (high-density interconnect), and RPCB (rigid printed circuit board) technologies.

Thailand’s Economic Context and Strategy

As Southeast Asia’s second-largest economy, Thailand faces the challenge of revitalizing a sluggish economy that has experienced modest growth in recent years. The Bank of Thailand has projected growth of 2.2% for 2025, highlighting the urgent need for foreign direct investment to stimulate economic activity and create employment opportunities.

The Thai government has implemented various strategies to attract high-quality investment, including tax incentives, streamlined regulatory processes, and targeted support for specific industries deemed critical to national development. The electronics sector, particularly advanced components like PCBs, has emerged as a priority area for development.

This investment approval aligns with Thailand’s broader economic transformation strategy, which aims to move beyond traditional manufacturing and assembly operations toward higher-value activities such as advanced manufacturing, research and development, and design capabilities. The country seeks to leverage its skilled workforce, strategic location, and established infrastructure to attract multinational corporations looking to diversify their supply chains.

Narit Therdsteerasukdi provided context on the broader investment landscape, stating that from 2023 to November 2025, Thailand received BOI promotion applications in the PCB-related segment—covering PCB production, printed circuit board assembly (PCBA), and key PCB raw materials—totaling 214 projects with combined investment of more than 300 billion baht. This wave of investment has helped position Thailand as ASEAN’s leading PCB production base and among the top five globally.

The Strategic Importance of Prachin Buri

The selection of Prachin Buri province as the location for this massive investment reflects careful strategic planning. The province offers advantages including industrial land availability, infrastructure connectivity to Bangkok and other major economic zones, and proximity to educational institutions that can supply skilled labor.

Peng Shen Technology (Thailand) acquired over 40 hectares of land in Prachin Buri Province in December 2023, initiating construction of what will become a major PCB production base. The facility’s design incorporates advanced manufacturing technologies and automation systems, positioning Thailand at the forefront of modern electronics production capabilities.

Workforce Development and Educational Partnerships

Beyond establishing manufacturing capabilities, the joint venture has placed significant emphasis on human resource development and knowledge transfer. Peng Shen Technology (Thailand) has signed cooperation agreements with leading Thai educational institutions to develop science and engineering curricula and conduct research related to the PCB industry and advanced electronics.

Partner institutions include King Mongkut’s Institute of Technology Ladkrabang, King Mongkut’s University of Technology North Bangkok, Kasetsart University, the National Institute of Development Administration (NIDA), and Sirindhorn International Institute of Technology (SIIT) at Thammasat University.

These partnerships aim to support high-quality workforce development and strengthen Thailand’s semiconductor and electronics capabilities over the long term. By aligning educational programs with industry needs, the initiative ensures that Thai workers will possess the specialized skills required for advanced manufacturing roles, creating a sustainable talent pipeline for the growing electronics sector.

Narit Therdsteerasukdi commented on this aspect of the investment, stating that such high-tech investments create quality jobs, build Thai skills and know-how, and strengthen Thailand’s position as it moves toward advanced technologies—particularly the development of the country’s semiconductor industry in the next phase.

Thailand’s Emergence as an Electronics Hub

The investment from ZDT represents more than just a single manufacturing facility. It signals Thailand’s emergence as a critical hub for electronics manufacturing within the Association of Southeast Asian Nations (ASEAN) and globally. The country has successfully attracted a wave of PCB investments over the past three years, transforming its industrial landscape.

This concentration of PCB manufacturing capabilities strengthens Thailand’s position in the global electronics supply chain, providing a foundation for further development of related industries including semiconductor packaging, electronic assembly, and ultimately more sophisticated electronic products. The presence of major global players like ZDT also creates ecosystem benefits, attracting suppliers and supporting industries to establish operations in Thailand.

The timing of this investment aligns with broader trends in the global electronics industry, including supply chain diversification, rising demand for advanced electronics, and geopolitical considerations that have prompted companies to establish manufacturing bases outside traditional centers like China. Thailand’s stable political environment, established manufacturing culture, and improving infrastructure make it an attractive alternative location.

As major PCB factories begin gradually commencing operations from 2025 onward, Thailand is poised to capture an increasing share of global PCB production. This development contributes directly to economic growth and industrial upgrading, supporting the country’s transition toward higher-value manufacturing activities.

Broader Implications for the Region

The successful attraction of this investment has implications beyond Thailand’s borders. It demonstrates how Southeast Asian nations can successfully compete for high-value manufacturing investments by offering strategic advantages, skilled workforces, and supportive government policies. As global supply chains continue to evolve, the region is becoming increasingly important for electronics manufacturing.

The investment also reinforces trends toward regionalization of supply chains, where companies establish production bases closer to end markets or in geopolitically stable locations to reduce risks. For ASEAN countries, this presents opportunities to climb the value chain in electronics manufacturing, moving beyond simple assembly to more sophisticated production activities.

Thailand’s success in securing this investment may prompt other regional competitors to enhance their own value propositions, potentially leading to increased investment incentives, infrastructure improvements, and workforce development programs across Southeast Asia. This competitive dynamic could ultimately benefit the region by accelerating industrial development and technological capabilities.

Looking forward, the establishment of advanced PCB manufacturing capabilities in Thailand positions the country to capture opportunities in emerging technology sectors including electric vehicles, renewable energy systems, advanced telecommunications infrastructure, and AI computing hardware—all of which rely heavily on sophisticated PCB technologies.

What to Know

- Thailand’s Board of Investment approved a 65 billion baht ($2.08 billion) investment from a joint venture between Taiwan’s Zhen Ding Technology (ZDT) and Thailand’s Saha Pathana Inter-Holding

- Zhen Ding Technology is the world’s largest printed circuit board (PCB) manufacturer, having held this position since 2017

- The investment covers four consecutive PCB manufacturing projects in Prachin Buri province and is expected to create 5,600 jobs

- PCBs are essential components in almost all electronic devices, from smartphones and medical equipment to telecommunications and energy infrastructure

- The Thailand facility represents ZDT’s first and only manufacturing base outside China and Taiwan

- From 2023 to November 2025, Thailand received 214 PCB-related investment applications totaling over 300 billion baht

- The joint venture has partnered with five Thai universities to develop curriculum and research in PCB technology and advanced electronics

- Thailand aims to become ASEAN’s leading PCB production base and rank among the top five globally

- The first phase of production began in September 2025, with expansion projects now approved

- This investment supports Thailand’s strategy to transition toward higher-value manufacturing and advanced technology sectors