The Fall That Stopped the Show

Hundreds of shoppers gathered at the MixC mall in Shenzhen this past weekend expecting to witness the future of robotics. Instead, they saw the future fall flat on its face. Xpeng Motors, the Chinese electric vehicle manufacturer known for its sleek electric cars, brought its latest creation, a humanoid robot named Iron, to the shopping center for its first public demonstration. The robot, standing 178 centimeters tall and weighing 70 kilograms, had already completed several successful walks across the stage, demonstrating what the company describes as a model-like gait designed to mimic human movement with unusual grace and fluidity.

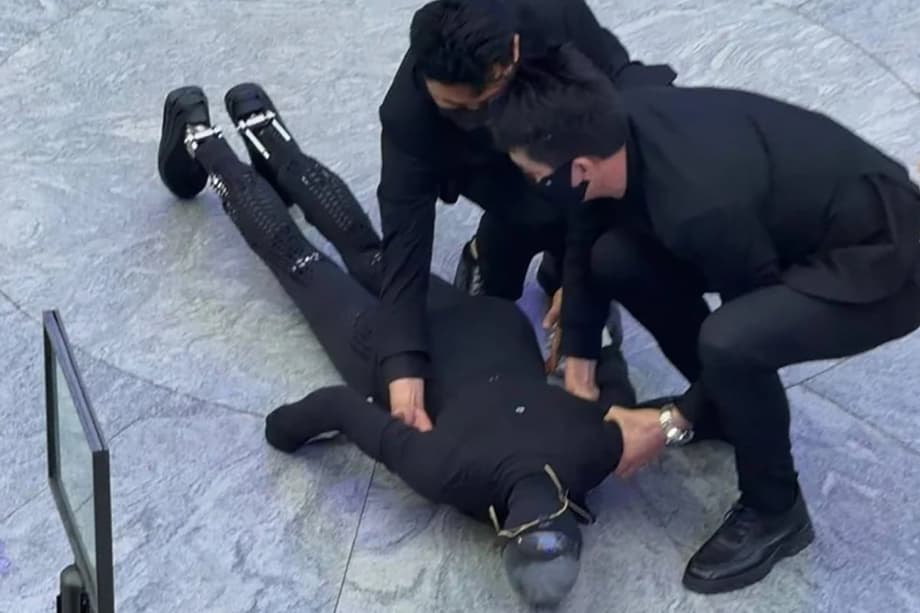

Then, during a moment of stillness, Iron lost its balance. The machine tipped backward, unable to catch itself, and crashed onto the stage with a sound audible to the front rows. Staff members rushed forward to break the fall, but the robot ended up face down on the ground, requiring handlers to carry it away for repairs and adjustments. The incident, captured on numerous smartphones and shared across Chinese social media platforms within minutes, transformed what was meant to be a showcase of technological prowess into a viral moment that highlighted the persistent gap between robotic ambition and mechanical reality in the emerging humanoid sector.

A Choreographed Debut Goes Off Script

The Shenzhen demonstration represented a significant milestone for Xpeng’s robotics division. The company had spent over a year refining Iron’s second-generation hardware, focusing on movement, control, and balance systems to create a machine capable of navigating human environments. The robot featured a five-degree-of-freedom spine modeled after human anatomy, synthetic muscles that stretch and contract to create fluid motion, and a sophisticated hip structure engineered to improve stability during complex movements. With 62 active joints and hands possessing 22 degrees of freedom each, Iron was designed to handle everything from delicate tools to bulky objects while maintaining a walking speed of up to 2 meters per second.

During the Saturday performance, Iron successfully executed a choreographed catwalk to the center of the audience area, interacting with children and posing trivia questions, including one about the color of giant panda feces. However, while standing still on stage, the robot’s balance systems failed. Videos circulating online show the machine wobbling before collapsing backward, drawing audible gasps from the crowd. Event staff quickly removed the unit, and a replacement robot continued the demonstrations. By Sunday, the second day of the campaign, Xpeng had modified the presentation, keeping Iron strapped to a support frame during educational exchanges with the audience rather than allowing it to walk freely.

The Technology Inside Iron

Despite the public stumble, Iron represents a sophisticated engineering effort that merges advanced artificial intelligence with biomimetic hardware. The robot’s internal structure incorporates a 3D-printed lattice layer called fascia, positioned beneath its outer suit, which mimics human musculature and helps dampen vibrations that typically create jerky movements in bipedal machines. This design choice reflects Xpeng’s philosophy of extreme anthropomorphism, an approach that prioritizes human-like appearance and movement to reduce the uncanny valley effect, the psychological discomfort humans feel when interacting with nearly-human objects that behave mechanically.

Power and Processing

Iron operates using an all-solid-state battery, a significant departure from conventional lithium-ion cells that use liquid electrolytes. This power source offers higher energy density, reduced weight, and increased safety, addressing concerns about heat generation and fire risks in robots operating near humans. The computational heart of the machine consists of three custom Turing AI chips, delivering approximately 2,250 to 3,000 trillion operations per second. This processing capability supports Xpeng’s Vision-Language-Action system, which links visual perception directly to physical movement, allowing the robot to respond intelligently to its surroundings in real time without lag or hesitation.

Learning to Walk Like Humans

Developers trained Iron’s movement algorithms on thousands of hours of human walking footage, enabling the robot to absorb shock through its foot joints when navigating hard surfaces like concrete or tile. The machine stands 5 feet 10 inches tall and weighs 154 pounds, dimensions chosen to make it approachable and practical for retail environments. A curved display wraps around its head, functioning as a dynamic face capable of changing expressions during communication. The company even designed the robot with adjustable body proportions and selectable gender characteristics, allowing customization for different social contexts and applications ranging from customer service to guided tours.

Executive Response Frames Failure as Progress

He Xiaopeng, co-founder and chief executive officer of Xpeng Motors, took to Weibo, China’s popular microblogging platform, to address the incident publicly within hours of the fall. Rather than treating the stumble as a setback or engineering failure, he positioned it as an expected stage in technological development and iterative improvement. He Xiaopeng drew a direct comparison between the robot’s tumble and childhood development, suggesting that such mistakes represent valuable learning opportunities rather than fundamental flaws in the hardware or software systems.

It reminds me of how all toddlers learn to walk. After a fall, they will stand firm; the next step is to begin running, and to keep running.

This framing attempts to shift public perception from viewing the incident as a malfunction to understanding it as part of a natural progression toward reliable bipedal locomotion. Interestingly, Xpeng’s vice president noted that the fall actually helped prove the robot was genuinely autonomous and not remotely controlled by a hidden human operator, addressing skepticism that had emerged online regarding the authenticity of Iron’s earlier smooth performances. The executive team appears to view the incident as a data point in the development cycle, emphasizing that public testing exposes weaknesses that laboratory environments cannot replicate.

The response reflects a broader strategy within the robotics industry to normalize public failures as part of the development process, similar to how autonomous vehicle companies treat minor accidents as learning opportunities rather than catastrophic setbacks. The authenticity debate had gained traction online after previous demonstrations showed Iron moving with unusual smoothness, leading some viewers to speculate that a human performer might be controlling the machine remotely. The unplanned fall effectively silenced these rumors, as no human operator would deliberately program a public failure. Xpeng’s team used the moment to highlight that the robot operates autonomously, processing environmental data through its onboard Vision-Language-Action system rather than following pre-programmed scripts or remote commands.

The Hard Reality of Bipedal Robotics

The incident highlights a persistent challenge in the robotics industry: creating machines that can navigate human environments with the same stability and adaptability as biological organisms. While artificial intelligence has made remarkable progress in cognitive tasks such as language processing and image recognition, physical embodiment remains far more difficult to master. Unlike wheeled robots or flying drones, bipedal machines must solve the complex mathematical problem of dynamic balance in real time, adjusting hundreds of times per second to compensate for shifts in weight distribution and external forces. Zhang Qiang, director of the academic committee at the Beijing Innovation Center of Humanoid Robotics, explained that comprehensive data on human movement remains scarce, making it difficult to train robots to handle the infinite variables of real-world terrain, unexpected disturbances, and static balance requirements.

Market analysis from GF Securities, a prominent Chinese investment bank, notes that non-humanoid robots, particularly quadrupedal robotic dogs, have achieved commercial success faster than their two-legged counterparts. These four-legged machines offer superior payload capacity, exceptional balance capabilities, and simpler control systems. They are also easier to design and maintain, giving them practical advantages in industrial and security applications where human appearance provides no functional benefit. The report suggests that quadrupedal designs possess higher stability and require less complex engineering to achieve reliable movement.

Humanoid robots face unique physics challenges. Standing on two legs creates a inherently unstable inverted pendulum problem, requiring constant micro-adjustments to maintain equilibrium. When stationary, robots like Iron must actively balance rather than resting, as humans do using passive biological structures and reflexes. The energy requirements for maintaining this constant adjustment are substantial, draining batteries faster than static or wheeled designs and generating heat that can affect sensor accuracy and motor performance over extended operation periods. The complex spine and waist mechanisms that enable lifelike movement also introduce additional points of potential failure, creating a trade-off between aesthetic realism and mechanical reliability that manufacturers must navigate carefully.

Commercial Ambitions Face Public Scrutiny

Xpeng has announced aggressive timelines for bringing Iron to market, targeting mass production by the end of 2026 with output ramping up in early 2027. The company aims to produce 1 million units by 2030, starting with deployment in retail settings where the robots will handle reception duties, guided tours, and customer assistance. Baoshan Iron & Steel has already partnered with Xpeng to test the robots in industrial monitoring roles, checking equipment for wear and potential failures before they cause production stoppages.

However, the Shenzhen stumble triggered a modest decline in Xpeng’s stock price, listed under ticker 9868 in Hong Kong and XPEV in the United States. Investors expressed concerns about durability and the readiness of the technology for commercial deployment. Market analysts noted that while the dip was minor, it reflects investor sensitivity to public perception of robotics companies, where demonstrations of weakness can affect valuation more than technical specifications. The attention also drew scrutiny from competitors in the humanoid space, including Tesla’s Optimus program and Boston Dynamics, which have faced their own challenges with public demonstrations. The incident became the fourth most searched topic on Baidu by Monday morning and the top trending topic on ByteDance’s Jinri Toutiao platform on Sunday night, according to data from Entobit.cn, which tracks social media trends across China. The widespread attention suggests that public appetite for humanoid robots remains high, even when the demonstrations reveal current limitations.

The public nature of the failure raises questions about whether companies should test such experimental technology in controlled environments before subjecting it to the unpredictability of shopping malls filled with spectators, children, and hard surfaces. While laboratory demonstrations can showcase ideal performance under optimal conditions, real-world deployments expose robots to vibrations, uneven flooring, and the psychological pressure of public expectation. Some analysts suggest that gradual rollouts in semi-controlled environments might build public trust more effectively than high-profile stumbles.

What Comes Next for Humanoid Robots

Despite the setback, Xpeng remains committed to its humanoid robotics program. The company views public demonstrations, even those resulting in falls, as valuable opportunities to gather data on human-robot interaction and real-world performance under unpredictable conditions. The choice to debut Iron in a retail environment rather than a factory or private home reflects a strategy of accelerating learning through social exposure, accepting that early versions will experience missteps as they navigate complex human spaces filled with variables impossible to simulate in development labs.

The robotics industry continues to pursue humanoid designs despite the technical challenges because human environments are built for bipedal navigation. Stairs, doorways, countertops, and tools all assume operators with two arms, two legs, and human-scale dimensions. A robot that can function in these spaces without requiring infrastructure modifications offers greater flexibility than specialized industrial equipment, even if achieving reliable locomotion takes longer and involves public failures along the way. The economic potential of machines that can seamlessly replace or assist human workers in existing workspaces drives continued investment despite the difficulties. Industry observers expect similar stumbles from other manufacturers as they move prototypes from labs to public spaces, suggesting that the race to commercialize humanoid robots will include more visible failures before achieving reliable performance.

For now, Iron’s fall serves as a reminder that humanoid robots remain experimental technology learning to navigate physical reality. The path from laboratory curiosity to reliable commercial product requires not just software intelligence but robust hardware capable of withstanding the inevitable falls that come with learning to walk, run, and work alongside humans in shared spaces.

The Bottom Line

- Xpeng’s Iron humanoid robot fell backward during its first public demonstration at a Shenzhen shopping mall, requiring staff intervention to remove the unit from the stage.

- The incident went viral across Chinese social media, becoming a top trending topic on multiple platforms and causing a modest decline in Xpeng’s stock price following the weekend demonstration.

- CEO He Xiaopeng compared the fall to toddlers learning to walk, framing it as a normal part of technological development rather than an engineering failure.

- Iron features advanced specifications including 62 active joints, solid-state batteries, and three Turing AI chips, but faces inherent challenges in bipedal balance and stability.

- Xpeng plans mass production by late 2026 with initial deployment in retail environments, despite the technical hurdles demonstrated during the public debut.

- The fall highlights the gap between laboratory demonstrations and real-world reliability in humanoid robotics, where physical embodiment remains more difficult than artificial intelligence development.