A live testbed for disaster response and everyday AI helpers

Humanoid robots are no longer stage props. They are the headline act at the 2025 International Robot Exhibition in Tokyo, where crowds packed into Tokyo Big Sight to watch machines put out fires, tidy offices, and even dance. The biennial showcase runs through Saturday and gathers a record 673 companies and organizations from Japan and abroad. With a theme of Sustainable Societies Through Robotics, the focus this year is on practical systems that collaborate with people in real environments, from disaster zones to shop floors and public spaces.

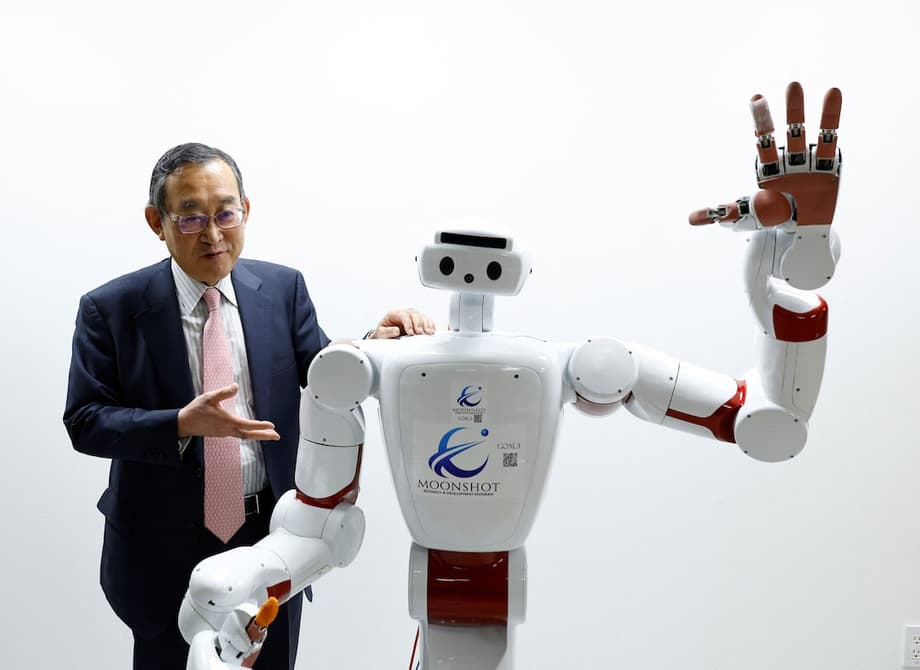

Kawasaki Heavy Industries drew steady attention with the latest model of its Kaleido humanoid. In a live drill, the robot tracked commands and extinguished a staged blaze with a fire hose, lifted a toppled shelf weighing 30 kilograms, then located and carried to safety a toy cat used as a stand in for a victim. Kawasaki engineers continue to favor a human sized design so the machine can wear standard protective gear and handle the same hardware firefighters or rescue crews already use.

Why humanoid form matters

The human body plan, two arms, two legs, and a torso, gives robots reach and access in spaces that are built for people. Doors, staircases, hand tools, and safety equipment were all designed for human proportions. A human sized robot can step through a doorway, climb stairs, twist a valve, and shoulder a hose without major redesign of the environment. That reduces the cost of deployment because teams can bring robots into existing buildings and infrastructure without refitting.

Kawasaki Managing Executive Officer Matsuda Yoshimoto said the company is aiming for machines that support people where conditions are hazardous and where collaboration is essential.

Robots can perform tasks at disaster hit areas where people cannot step in. Humanoids can also use the same tools as humans. I want to build robots that can work alongside humans.

Most of the humanoids on show mix autonomy with teleoperation. Operators can guide a task from a safe distance when precision or judgment is required, while onboard software processes camera images, identifies objects, plans footsteps, and balances the body in real time. This blend keeps a human decision maker in the loop while letting the robot carry the weight, reach into danger, and repeat physically demanding steps without fatigue.

From disaster scenes to office work

Beyond rescue drills, exhibitors stressed everyday usefulness. Yaskawa Electric, working with SoftBank, built a near future office set where a physical AI robot scanned the room through a camera, recognized clutter within seconds, and moved to clean and put items back. The sequence showed how robots can respond to simple commands and tidy shared spaces after a meeting or at the end of a shift. Kawasaki also showed domestic routines such as raking leaves and taking out trash, hinting at a path from high risk missions to household chores.

Keeping people at a safe remove was another recurring theme. Man Machine Synergy Effectors integrated a humanoid upper body with an aerial work platform. A worker wearing virtual reality goggles could see through the robot’s viewpoint and control its arms to tighten fittings or clear debris. That setup is aimed at jobs like railway maintenance or timber felling, where elevation, heavy parts, or unpredictable terrain raise the risk for crews. Teleoperation lets an experienced technician apply skill and discretion while the robot bears the exposure.

Inside the demos that drew crowds

Fanuc highlighted a robotic arm with AI that could understand spoken instructions, then use a camera to locate specific objects. In one demo, a visitor asked the arm to pick up dice and arrange them so each showed the number five. The system detected three dice, grasped them one by one, rotated faces to five, and placed them in position. Voice and vision together cut programming time and make complex tasks easier for non specialists.

Entertainment drew cheers as well. GMO Internet Group programmed a humanoid dancer that jumped, turned, and kept time with music on a small stage. The company also worked with a Unitree robot to stage a dance off, showing agile motion and balance. Kawasaki displayed its personal mobility device Corleo, while Unitree exhibited its Go2 W robot dog that adds wheels to legs for speed and stability. Displays blended novelty with practical functions like customer service, where a robot can take orders or carry items through a crowd.

- Put out a mock fire using a hose

- Lift a 30 kilogram shelf to clear a path

- Locate and carry a toy cat during a rescue drill

- Clean and organize an office after a meeting

- Perform rail maintenance with remote control from VR goggles

- Cross obstacles and keep balance during dance routines

- Prepare treats at a booth to show precise manipulation

AI brains, remote hands, and tactile sensing

Behind the showmanship is a quiet shift in capability. Machine learning lets robots recognize a scene, segment objects, and anticipate how items will move as they are pushed or lifted. Pretrained vision models help with perception. Policy models map from images and goals to hand or foot actions. Low level control still matters too, since a humanoid must keep balance while manipulating with both hands. Developers at the show framed these systems as physical AI, software that understands and acts in the physical world.

Touch is the other missing sense that engineers are now adding. Tactile sensors in robot hands measure minute forces and shear, revealing whether a grip is slipping or a surface is fragile. At several booths, vendors demonstrated dexterous hands that could pick up a test tube, cradle a sphere, or stack small cubes without cracking or dropping them. PaXini showed a new generation of tactile sensors and a dexterous hand, part of a push to give robots feedback that is closer to human skin.

Tomohiro Uchida of GMO said the focus on movement quality is paying off as control algorithms and actuators improve.

Robots have become much more fluid in their movements in recent months. Humanoid robots can help fill gaps in the declining labor force.

Together, these advances point toward robots that can be safely trusted with a broader slice of work while people supervise, set goals, and handle exceptions.

Market momentum and global rivalry

The exhibition drew more than 670 organizations from Japan, China, the United States, and other regions, a breadth that reflects intense investment in humanoids and flexible industrial systems. Companies emphasized collaboration rather than replacement, with robots taking on repetitive, risky, or physically heavy tasks. Demand is rising as many economies face shrinking workforces and as cities plan for earthquakes, floods, and fires. Competition is evident in locomotion, manipulation, and the AI that connects perception to motion.

Cost, endurance, and reliability still shape the path to wide adoption. Batteries need to power legs and arms through a full shift. Hardware must survive dust, water, and temperature swings. Safety certification and training programs will take time so that robots can work in warehouses, stations, and clinics without creating fresh hazards. Many exhibitors leaned on hybrid control, autonomy for routine steps and human teleoperation for judgment calls, as a safe bridge to broader deployment.

What visitors need to know

The 26th International Robot Exhibition opened Wednesday at Tokyo Big Sight in Koto Ward and runs through Saturday. Organizers divide displays into an industrial robot zone and a service robot zone. Visitors can expect welding and assembly cells on one side and service systems on the other that include personal assistance, cleaning, agriculture, space, and public safety.

Organizers say a record 673 companies and organizations are participating, and attendance is expected to exceed 150,000 across the four days. Admission is priced at 1,000 yen, and entry is free for junior high school students and younger children. The show is designed for professionals and curious families alike, with many booths inviting hands on interaction and photo friendly demos.

Key Points

- Humanoid robots lead iREX 2025 at Tokyo Big Sight, running through Saturday.

- Kawasaki’s latest Kaleido performed fire, lift, and rescue drills.

- Yaskawa and SoftBank presented a near future office with a cleaning robot that recognizes messes.

- Fanuc showed a voice guided AI arm that arranged dice to five.

- GMO staged a dancing humanoid and a performance with a Unitree robot.

- Man Machine Synergy Effectors demonstrated VR teleoperation for rail and forestry work.

- PaXini displayed tactile sensors and a dexterous hand for delicate tasks.

- More than 670 exhibitors attend, and over 150,000 visitors are expected.

- The theme is Sustainable Societies Through Robotics with an emphasis on human robot collaboration.

- Tickets are 1,000 yen, with free entry for junior high students and younger children.