A humanoid that moves like a person

On a brightly lit stage in Guangzhou, Xpeng introduced its next generation humanoid robot, IRON, with a walking demo so smooth that it immediately set social feeds alight. The robot glided with a model like stride, shifted its weight from hip to hip, and kept balance with foot and toe control that looked human. The reveal was a centerpiece of the companys AI Day, and it signaled a serious bet on physical AI, a strategy that merges custom chips, a new vision first AI brain, and bionic mechanics that mimic the human body.

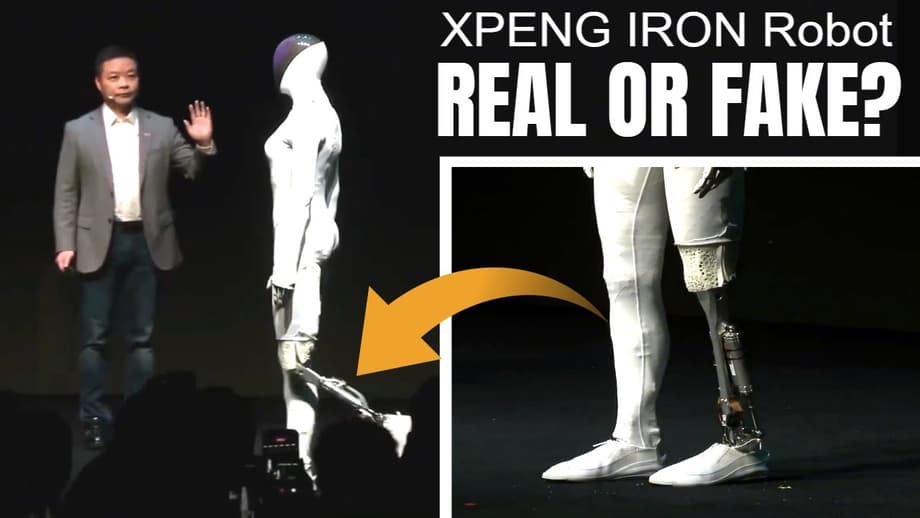

The performance was so lifelike that many viewers wondered if a person was inside a shell. The company answered the doubt in dramatic fashion. An engineer carefully cut open a section of the outer covering on stage, exposed the metal bones and actuators in a leg, then sent IRON walking across the floor again. The demonstration left little room for trickery. What people saw was a machine designed to move like a person and it did.

Xpeng positions IRON as a service companion for busy public spaces, from car showrooms to malls and office lobbies. The first deployments are planned in the companys own locations in 2026, with broader commercial rollouts to follow. Mass production is targeted for the end of 2026, backed by self developed computing chips and a software stack shared with the companys cars and robotaxis.

What makes IRON look so human

IRONs design follows the human template from the inside out. A flexible spine and a network of bionic muscles let the torso bend, twist, and recover balance with poise. The outer layer is full coverage synthetic skin that feels warm to the touch, a deliberate choice to make interactions less cold than bare metal or hard plastics. A 3D curved display wraps part of the head, turning the face into a dynamic canvas that can show simple emotions or useful cues like service status.

Fine motion comes from a dense array of joints. Xpeng says IRON supports 82 degrees of freedom across the body, with 22 degrees of freedom in each hand to grasp delicate objects and gesture like a person in conversation. Engineers even added passive motion at the toes to smooth the heel to toe roll that makes a stride look natural. Small harmonic joints help achieve a one to one hand size, which keeps tools and everyday objects within reach of human scale ergonomics.

The AI brain and chips inside

Movement alone does not produce convincing behavior. IRONs control stack is built around a vision centered model that maps what the robot sees to what it should do next with minimal detours. Xpeng describes this as a Vision to implicit token to action path. In practice, that means the robot does not pause to convert images into words before it decides on a motion plan. It recognizes a scene, predicts intent, and moves.

Why skipping language can speed up actions

Language is powerful for dialogue and planning, yet it can add latency when a system just needs to step aside or pick up a dropped card. By learning patterns that link visual input to motor output directly, a robot can shorten the gap between perception and control. For a biped that must balance and adjust foot placement many times each second, lower delay is a big deal. People take this for granted. Robots must earn it.

The compute platform leaves headroom for those fast loops. IRON carries three Turing AI chips that together deliver about 2,250 TOPS of on board performance. TOPS stands for trillion operations per second, a measure of how many mathematical steps the processors can complete. That budget supports several neural networks at once, including perception, dialogue, and motion, without offloading to a distant server. Some presentations from the event referenced a higher effective number for specific modes, but the clear story is a compact compute stack that runs in real time on the robot.

Above the chips sits a multi model architecture that blends different skills. VLT, or Vision Language Task, acts as a core engine for goal driven behavior. VLA, or Vision Language Action, inherited from the automotive team, handles the 82 joints with continuous control. VLM, or Vision Language Model, supports conversation and instruction following. Working together, these brains let IRON talk with a guest, perceive a scene in a store, then walk, point, and hand over a brochure in a single flow.

Energy, safety, and privacy

Xpeng says IRON is the first humanoid to run on an all solid state battery. In a typical lithium ion cell, the electrolyte that carries charge is a liquid. Solid state designs use a solid electrolyte instead. That change aims to improve thermal stability and reduce fire risk, which matters for a robot that will stand next to people in enclosed spaces. Solid electrolytes can also raise energy density, which helps a mobile robot run longer without a heavy pack.

Safety is not only about the pack. IRON supports indoor automatic emergency braking, the same concept many drivers know from advanced driver assistance in cars. If sensors detect a person or a glass wall that the robot did not anticipate, the controller can slow or stop to avoid contact. Xpeng also introduced a data rule that echoes classic science fiction lore. Beyond Asimovs three laws, the company adds a fourth: a robots duty to keep personal data private. The claim is that sensitive user information should not leave the device, which fits with the heavy on board compute and reduces reliance on cloud processing for routine tasks.

Use cases start in stores, not factories

Humanoids still face durability, cost, and maintenance questions in heavy industry. Xpeng is approaching deployment in stages. The first stop is public facing service. The plan is to place IRON in the companys retail stores starting in 2026. There, the robot can greet visitors, guide them through exhibits, answer product questions, or direct traffic during busy launches. These are structured settings with staff on hand, a good proving ground before tougher work.

To speed up new skills, Xpeng will open a software development kit so outside teams can build applications. A store might want a branded concierge. An office could need a badge check assistant. A museum might script a guided tour that syncs the robots speech with a video wall. Because the robot shares AI foundations with Xpengs vehicles, the same perception and planning tools that spot a stroller at a crosswalk can help a greeter notice a child who stepped away from a parent.

Industrial pilots with Baosteel

While large scale factory deployment is not the first target, Xpeng named Baoshan Iron and Steel as an ecosystem partner. IRON units will enter steel facilities for trials in tasks such as inspection and routine rounds. These pilots give the team real data on heat, dust, and vibration, and they help define what a humanoid would need to survive long shifts in a plant. Lessons from those trials are likely to flow back into future builds.

Customization and social presence

Service roles are social, and IRONs appearance reflects that. The platform supports different body shapes and sexes, hairstyles and colors, and clothing that fits brand settings. The hands are sized like a persons hands for natural handoffs. The synthetic skin covers the frame and is tuned for warmth so a handshake does not feel like plastic. The head mounted curved display can show expressions and simple animations, which makes it easier for a visitor to tell if the robot is listening, thinking, or finishing a task.

Dexterous hands with 22 degrees of freedom per side are key for useful service work. They let IRON form readable gestures while speaking, hold a phone to scan a code, pick up a brochure without crumpling it, or carry a small box while keeping balance. Paired with the flexible spine and toe compliant feet, the hand control helps keep the entire posture stable when leaning, reaching, or stepping around a display stand.

How IRON compares with other humanoids

Humanoid robots are moving from lab demos to staged trials around the world. Tesla shows regular progress with Optimus. Boston Dynamics, long known for dynamic jumping and running, is pivoting Atlas toward industry. Chinese players like Unitree are pushing fast cycle updates. Xpeng is carving out a different niche for now. The company emphasizes lifelike social presence, a soft skin body, and on device privacy rules for public spaces, backed by a solid state pack that suits indoor use. That profile aims at service tasks rather than heavy lifting on day one.

Walking on two feet is still hard for machines. Humans balance with micro corrections in the ankles, knees, hips, and spine, and we do it without thinking. Robots need thousands of timed commands for the same effect. Xpengs approach blends data driven motion learning with careful mechanical design, such as passive toe motion and a human scale hand and shoulder layout. The result is a stride that looks less robotic and hands that can do more than simple clamps. The proof of utility will come from hours on the floor, not a short runway walk, yet the public demo showed a system that is ready to start collecting that time.

From cars to robotaxis and flying systems

IRON is part of a wider push that Xpeng calls physical AI. The same vision centered model that runs the robot also powers driver assistance in the companys vehicles and a robotaxi program set to expand with new cars next year. The stack is built to run on the firms own chips with high redundancy in vehicles. Xpeng has also introduced low altitude products under the ARIDGE brand, including a modular ground vehicle that carries a small electric vertical takeoff aircraft. The combined message is that the company is not just an automaker. It is building a suite of AI defined machines that move through traffic, across showrooms, and eventually into the sky.

At a Glance

- Xpeng unveiled the next generation IRON humanoid robot at AI Day in Guangzhou with a lifelike stage walk.

- Engineers cut open part of the robots leg covering on stage to show mechanical internals and dispel doubts.

- IRON features a flexible spine, bionic muscles, full coverage synthetic skin, and a head mounted 3D curved display.

- The robot supports 82 degrees of freedom across the body and 22 per hand for dexterity.

- A vision centered AI stack maps perception directly to action, reducing delays in balance and grasping.

- Three Turing AI chips provide about 2,250 TOPS of on board compute for perception, dialogue, and control.

- Xpeng says IRON is the first humanoid to use an all solid state battery, aimed at safer indoor operation.

- Indoor automatic emergency braking helps the robot avoid people and obstacles in close quarters.

- Privacy rule adds a fourth law, stating user data should not leave the device during routine operation.

- Initial service roles include greeter, tour guide, and shopping assistant in Xpeng locations starting in 2026.

- Mass production is targeted by the end of 2026, with an SDK planned so developers can build new skills.

- Industrial pilots with Baosteel will test inspection and rounds in challenging plant conditions.