Design speaks in the produce aisle

Walk through a Japanese market in summer and the art is not only in the peaches and melons. It is printed right on the cardboard. For decades Japan has been famous for luxury fruits packaged like jewelry, from musk melons gleaming under tissue paper to rare Taiyo no Tamago mangoes that fetch auction prices in the hundreds of thousands of yen. The quiet surprise is how much care flows into everyday produce boxes. These containers are built to carry delicate food, and they double as billboards for place, season, and pride.

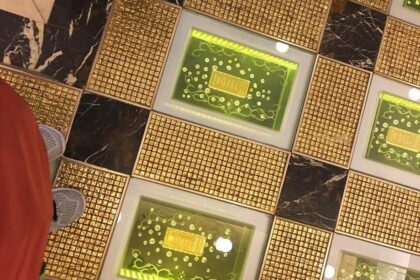

Watermelon is a case in point. Retailers compete on the fruit, and they compete on the box. A Niigata brand called Yairokko sends out cartons washed in pale green and white, a visual rhyme with the striated rind. In Kanazawa, designers simplify the fruit into a bold red circle with seeds. One seed is drawn with the five petal form of a kaga umebachi, a motif tied to the city in Ishikawa Prefecture. Shoppers do not need to read a word to know what is inside, where it is from, and why it matters to the producers who grew it.

These choices are rarely random. Japan celebrates packaging as a craft. Fruit boxes sit at the intersection of logistics and visual communication. They must stack, breathe, and protect. They also serve a cultural role. They signal freshness, they introduce a grower or a region, and they transform a simple purchase into a small story about place and season.

What makes these boxes work

Good fruit packaging begins with respect for the cargo. Cardboard strength, surface coatings that can handle condensation, and vents that let air move around the produce are standard considerations. Handles and clear up arrows encourage gentle handling. The print has a job too. Color and iconography help staff and shoppers identify variety and size at a glance on a busy dock or supermarket floor.

Inside the box, inserts do the quiet work. Molded trays cradle nectarines or grapes. Tissue paper cushions apples so skins do not scuff. Strawberries ride in rigid compartments that stop the fruit from colliding. These choices protect quality without asking the customer to read instructions.

Form meets function

Producers and cooperatives choose fluting and board thickness based on travel distance and humidity. Vents are placed to line up with pallets and chillers so cold air can circulate in storage. Die cut corners absorb bumps. Inks are chosen to resist smearing when boxes are damp. A clear mark for the top and bottom avoids pressure on delicate stems. Everything about the container is a modest engineering answer to the reality of moving fruit.

Clarity and honesty

Japanese consumer packaging has a tradition of straight communication. The idea carries into produce. Simple pictograms show seedless or seeded, early or late season, or how many pieces are in the tray. Typography is large and legible. Many boxes show the exact fruit in a clean, unembellished illustration rather than a fantasy image. The goal is trust, so the first look on the outside matches the experience on the inside.

Local pride printed on cardboard

Regional identity is perhaps the most charming aspect of Japanese fruit boxes. Designers weave local symbols into utilitarian cartons to turn them into small ambassadors of place. A watermelon from Niigata looks like rind on the outside. A Kanazawa seed doubles as a historical crest. The message is simple, this fruit is from here.

Yamagata growers have used a rising sun mark that also reads as a round watermelon, a neat play between national imagery and practical labeling. In Nagano, JA Matsumoto Highlands prints a serrated mountain line that locals associate with the prefecture. In the latest version, a slice of watermelon rises among the peaks on the side panel, an easy way to spot the product from two aisles away. The same mountain motif appears on lettuce and green onion packaging from regional cooperatives, which builds a family look across different crops.

Designers have fun with vegetables too. A box from Kunneppu in Hokkaido shows brown and white onions together, a wink to unpeeled and peeled. Garlic cartons from Oirase in Aomori sketch a bulb that can also be read as a nose, a visual pun that sticks in the memory. Mascots show up often, from Gunma chan holding an eggplant to a jaunty character named Vejita kun with a tomato head. These faces make stacks of boxes feel friendly rather than anonymous.

These cartons are not throwaway to everyone. Collectors post photos, and a few designs become minor hits. In one recent project in the Matsumoto area, junior high students turned regional produce boxes into miniature gachapon toys, complete with watermelon, Chinese yams, green onions, apples, and burdock. The capsule replicas sold locally and did what the full size boxes do every day, celebrate nearby farms.

Gift culture and the price of perfection

Fruit gifting runs deep in Japan. When people bring omiyage to colleagues or relatives, a flawless peach or a velvety melon in a handsome box carries a message of care. Retailers treat top grade fruit with ceremony. Staff nestle each piece in crinkled paper and present it in a rigid box that opens like a jewelry case. The ritual elevates produce into a special event.

Prices reflect the attention. A fancy melon can cost around 10,000 yen. Rare or first harvest fruits sold at auction across the country can reach much higher figures. Miyazaki Prefecture has become famous for Taiyo no Tamago mangoes with glowing red skin. They are selected under strict criteria for size and sweetness, and the best examples command premium prices. The box is part of the story. It signals rarity, and it protects a delicate surface that would bruise in a casual crate.

The prestige travels. Luxury strawberries from Kyoto have appeared in London at specialty food halls, sold in precise trays with every berry aligned. The fruit passes dozens of checks, is picked at just the right hour, chilled, and then shipped in packaging that fixes each strawberry in place. The experience at the counter in Tokyo or overseas is the same, open the lid and admire perfect fruit that looks like the illustration on the label.

Engineering for freshness

Fragile fruits such as strawberries require more than a pretty lid. Growers and packers in Japan combine meticulous grading with purpose built interiors. One approach, sometimes called a cradle style pack, seats each berry in its own compartment above a cushioned base. The tray prevents rubbing, the lid keeps humidity steady, and the dimensions guarantee the weight declared on the label. After the final check, the tray slips into a stiffer outer box for transport.

That interior is only half of the protection. Temperature is controlled from greenhouse to plane to store. Cold air needs space, so vents and spacers are calculated as part of the design. This attention to logistics is a reason peaches from Yamanashi or grapes from Nagano can travel to Hong Kong or Taiwan and arrive with their bloom intact. Packaging is a tool that preserves the handwork done by farmers during the growing season.

New technology is entering the picture. Smart packaging can carry time temperature indicators to flag breaks in the cold chain. Sensors can detect ethylene, the gas that speeds ripening, or monitor humidity and leaks. Some systems even use simple RFID tags to record a history of handling. These tools are still maturing, with questions about cost and waste, yet the direction is clear. Better information inside the box can mean fewer losses and better fruit for the customer.

Sustainability check

Fruit boxes sit in a tricky place in the waste discussion. Protection prevents damage, which prevents spoilage. Extra layers, especially plastic, carry a cost. Research on fruit packaging shows that smaller packs often have a higher plastic footprint per kilogram of fruit than larger ones. Boxed formats with polymer windows and rigid trays can have the highest embedded carbon in plastics per kilogram delivered.

Designers have options. Mono material solutions make recycling simpler. Trays formed from paper pulp reduce the use of mixed plastics. Print with water based inks and keep adhesive to a minimum. Resize boxes to match fruit so the packaging to product ratio is not excessive. Use cutouts for visibility instead of plastic windows. Each move shaves impact without asking growers to give up protection during transport.

Japan has a strong community of packaging engineers and a culture of design awards, and fruit boxes are part of that conversation. Many cooperatives already rely on recycled cardboard at the outer layer while keeping any plastic components light and removable. Returnable crates circulate in wholesale channels for short hauls. There is room to go further, and the best ideas tend to spread fast once a few large growers adopt them.

A long tradition of artistry

The idea of turning containers for food into art is not new in Japan. In the Meiji period, the lacquer artist Shibata Zeshin designed a tiered food box decorated with summer and autumn fruits. Grapes, melons, loquats, and pears shimmer across a dark ground in metal and colored lacquer. The piece was meant for festive servings, yet its subject was the same produce that fills market stalls today. A museum collection preserves the work for visitors who want to see how craftsmanship treated fruit as worthy of fine decoration.

You can view an example of this tradition at The Metropolitan Museum of Art, which holds a Zeshin food box with fruit motifs that dates to the late nineteenth century. The listing provides images and details about the techniques used in lacquer work. The museum page offers background on the object and maker.

Why the designs matter to farmers and shoppers

Packaging is marketing, and in produce that can feel like a paradox. Real fruit spoils, shapes vary, and the supply swings with weather. Thoughtful boxes give growers a constant voice in an unpredictable trade. A watermelon printed with the crest of a city or a mountain line from a valley says, this fruit comes from people and a place.

The commercial return is measurable. Boxes make sorting easier for grocers and distributors, which cuts mistakes. Shelves feel tidier. Shoppers remember distinct art and reach for it next time. Collectability, even as a small niche, can turn a commodity into a recognized brand. Projects such as student made gachapon versions of farm boxes are quirky proof that a strong visual identity wins attention beyond the produce aisle.

There is also a cultural benefit. Children spot mascots and learn the names of vegetables they might have ignored. Seasonal colors remind people what is ripening now. Gifts wrapped with care encourage gratitude for the work behind a single peach. When design, logistics, and care meet in a simple carton, fruit looks and travels better. Farmers gain pride, and customers gain confidence.

Key Points

- Japanese fruit boxes balance protection, clear communication, and regional storytelling

- Design motifs often reference local symbols, such as prefectural crests, mountains, or puns based on produce shapes

- Luxury fruit gifting sustains premium packaging that treats individual pieces like special items

- Purpose built interiors for strawberries, grapes, and peaches reduce bruising and keep quality high across long shipments

- Exports to nearby markets benefit from packaging that supports cold chain logistics and quick identification

- Smart packaging with simple sensors is emerging to cut waste and monitor transport conditions

- Reducing plastic, using mono materials, and resizing boxes can lower the packaging footprint without sacrificing protection

- Fruit containers in Japan continue a long tradition of making edible goods worthy of artistic presentation