Breakthrough in Frictionless Levitation: The Japanese Innovation

In a remarkable leap for miniature transport technology, researchers at Yokohama National University in Japan have unveiled an ultrafast, frictionless levitation device. This pioneering technology, which harnesses the power of sound waves, promises to revolutionize the way small objects are moved in fields ranging from electronics manufacturing to biomedical research. By eliminating friction—a persistent obstacle in traditional transport systems—this device opens the door to faster, more precise, and contactless movement of delicate components.

Friction has long been a limiting factor in the efficiency and speed of conveyor belts and other mechanical transport systems. The new device developed by the Yokohama team not only overcomes this challenge but does so in a compact, untethered form, allowing for omnidirectional movement and unprecedented agility. The research, published in Advanced Intelligent Systems on July 10, 2025, is already being hailed as a potential game-changer for industries that rely on the precise handling of miniaturized parts.

How Does the Ultrafast Levitation Device Work?

At the heart of this innovation is acoustic levitation, a technique that uses sound waves to suspend objects in mid-air. Unlike magnetic or pneumatic levitation—which require large, often cumbersome equipment—acoustic levitation can be achieved with a much smaller footprint, making it ideal for miniaturized applications.

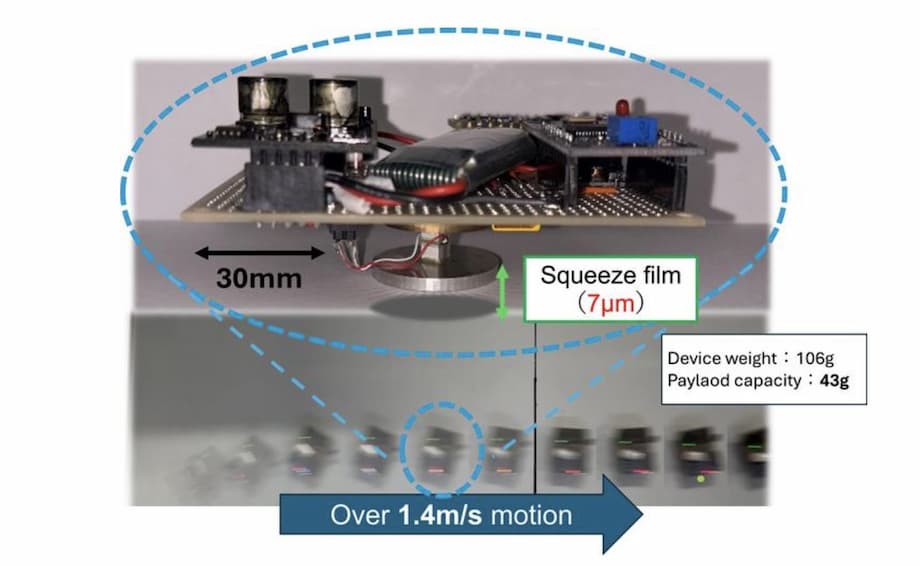

The device employs a piezoelectric actuator to generate high-frequency vibrations. These vibrations create a thin layer of fluid, known as a squeeze film, between two surfaces. When activated, this squeeze film acts as a cushion, lifting the object and allowing it to glide effortlessly in any direction. The result is stable, frictionless, and omnidirectional movement—without the need for external cables or tethers.

Overcoming the Limitations of Traditional Acoustic Levitation

One of the main drawbacks of earlier acoustic levitation systems was the reliance on cables for power and control, which often interfered with the precise positioning of levitated objects. The Yokohama team addressed this by integrating a wireless drive circuit, enabling the device to operate untethered. This innovation not only enhances the device’s agility but also makes it more practical for real-world applications where flexibility and freedom of movement are essential.

Performance and Capabilities

Experimental tests demonstrated the device’s impressive capabilities. When placed on a 10-degree incline, an object would slide down at a rate consistent with gravity if the device was turned off. However, when the levitation system was activated, the object could be propelled at speeds of up to three meters per second—far surpassing what is possible with conventional friction-based systems.

The device can achieve stable levitation and movement with a total load of up to 150 grams, and it can carry an additional payload of about 43 grams before losing its levitation capability. These specifications make it suitable for transporting a wide range of small, delicate items, from electronic components to biomedical samples.

Why Is Frictionless Levitation Important?

Friction is a fundamental force that resists the motion of objects in contact. In industrial settings, friction leads to wear and tear, energy loss, and limitations on speed and precision. For the transport of miniaturized items—such as microchips, tiny mechanical parts, or biological cells—friction can cause damage or contamination, making contactless methods highly desirable.

By eliminating friction, the new levitation device allows for:

- Higher speeds in moving small objects

- Greater precision in positioning and handling

- Reduced risk of damage to delicate components

- Cleaner transport by minimizing physical contact and contamination

These advantages are particularly significant in industries where even microscopic particles or vibrations can compromise product quality or research outcomes.

Applications: From Microelectronics to Medicine

The potential applications for this technology are vast. In the electronics industry, the device could streamline the assembly of microchips and other tiny components, reducing defects and increasing throughput. In biomedical research, it could enable the gentle, contactless transport of living cells or fragile samples, minimizing the risk of contamination or mechanical stress.

According to the research team, their long-term vision is to develop robots equipped with multiple levitation devices, capable of performing contactless delivery services for machine parts, biomedical cells, and other sensitive items. Such robots could operate in environments where traditional transport methods are impractical or where sterility is paramount.

Expert Insights and Industry Impact

Dr. Kenjiro Fukuda, a leading researcher in micro-robotics (not involved in the study), commented on the significance of the breakthrough:

“Contactless manipulation at high speeds and with high precision has been a longstanding challenge in robotics and manufacturing. The integration of wireless acoustic levitation with squeeze film technology is a clever solution that could unlock new possibilities for automation and miniaturized assembly lines.”

The ability to move objects without physical contact is also attracting attention from the biomedical sector. Dr. Yuki Tanaka, a biomedical engineer, noted:

“Transporting living cells or delicate tissues without touching them reduces the risk of contamination and mechanical damage. This technology could be transformative for lab automation and tissue engineering.”

How Does Acoustic Levitation Work?

Acoustic levitation relies on the principle that sound waves exert pressure on objects. When high-frequency sound waves are directed at an object from below, the resulting pressure can counteract gravity, causing the object to float. By carefully controlling the frequency and amplitude of the sound waves, researchers can stabilize the object and even move it in specific directions.

The squeeze film effect, generated by the piezoelectric actuator, further enhances this process by creating a thin layer of air or fluid that acts as a lubricant. This allows the levitated object to move smoothly and with minimal resistance, even on inclined or irregular surfaces.

Comparison with Other Levitation Technologies

Other forms of levitation, such as magnetic (maglev) and pneumatic systems, have been used in applications like high-speed trains and industrial conveyors. However, these systems often require large magnets, powerful electromagnets, or complex air pumps, making them unsuitable for miniaturized or portable applications.

Acoustic levitation, by contrast, can be implemented with compact components and does not require the object to have any special magnetic or conductive properties. This makes it especially attractive for handling a wide variety of materials, including non-magnetic and biological items.

Challenges and Future Directions

While the current device represents a significant advance, there are still challenges to address before it can be widely adopted. The maximum load capacity—currently around 43 grams for additional payload—limits its use to relatively small objects. The researchers are working to improve the efficiency of the levitation mechanism, enhance stability under heavier loads, and ensure reliable performance on uneven or irregular surfaces.

Another area of ongoing research is the integration of multiple levitation devices into coordinated robotic systems. By combining several units, it may be possible to transport larger or more complex items, or to perform intricate assembly tasks entirely without physical contact.

Broader Implications for Japanese Innovation

This breakthrough is part of a broader trend of technological innovation in Japan, particularly in the fields of robotics, automation, and transportation. For example, Japan is also exploring the deployment of driverless bullet trains and advanced sound insulation technologies in schools, reflecting a national commitment to leveraging science and engineering to address societal challenges.

As Japan faces demographic shifts and labor shortages, innovations like frictionless levitation could play a key role in maintaining productivity and competitiveness in high-tech industries.

In Summary

- Japanese researchers at Yokohama National University have developed an ultrafast, frictionless levitation device using acoustic technology.

- The device eliminates friction by creating a squeeze film with a piezoelectric actuator, enabling omnidirectional, untethered movement of small objects.

- Wireless drive circuits remove the need for cables, enhancing agility and practical usability.

- The technology is poised to revolutionize the transport of delicate items in electronics, biomedical, and chemical industries.

- Future improvements aim to increase load capacity, stability, and performance on irregular surfaces, with the ultimate goal of enabling contactless robotic delivery systems.