A new push to make components in India

India moved from assembling many devices to making their core parts after approving the first seven manufacturing projects under a 2.7 billion dollar Electronics Component Manufacturing Scheme. The government cleared investments of Rs 5,532 crore, equal to about 626 million dollars, to build plants for printed circuit boards, camera modules, copper clad laminates and polypropylene film. The program aims to curb dependence on imported parts, most of which come from East Asia, and to anchor more of the value chain at home.

- A new push to make components in India

- What the new scheme offers

- Where the first plants are coming up

- Why PCBs, camera modules and laminates matter

- The import gap India wants to close

- How ECMS ties into the semiconductor and PLI push

- Challenges that could slow progress

- Impact on states and jobs

- What to watch next

- The Bottom Line

In the year ended March 2025, electronics became India third largest export at 38.56 billion dollars. Imports of electronic components reached 36.8 billion dollars, nearly 40 percent supplied by China and more than 16 percent routed via Hong Kong. With trade controls reshaping access to advanced technologies and materials, New Delhi is trying to reduce risk in critical supply lines. Multinationals are already diversifying where they build. Apple shipments made in India rose 42 percent to 12.8 billion dollars in 2024. In the quarter ended September 2025, India surpassed China as the top smartphone exporter to the United States, helped by a sharp increase in output. The government says India is now the second largest mobile phone manufacturer.

The first batch of ECMS approvals spans five plants in Tamil Nadu and one each in Andhra Pradesh and Madhya Pradesh. According to government and industry briefings, these units are expected to supply about 20 percent of domestic demand for high density PCBs, roughly 15 percent for camera module sub assembly, and all of the need for copper clad laminates and polypropylene film. The same projects are projected to create more than 5,100 direct jobs and deliver output worth about Rs 44,406 crore, with around 60 percent of production geared for export.

What the new scheme offers

ECMS is a six year incentive program with a one year setup window and a budgeted outlay of Rs 22,919 crore. It seeks to draw in large global and domestic investments, close technology gaps in parts India still imports, and reward performance that builds competitive scale. The Ministry of Electronics and Information Technology designed the policy to move beyond final assembly. It directs support to components, sub assemblies and capital equipment that anchor the supply chain, and it pairs money with commitments on investment, output, quality and jobs.

Which parts come first

The targeted basket covers a broad set of building blocks. It includes bare PCBs, multi layer and high density interconnect PCBs, camera modules, electromechanical parts, lithium ion battery components, copper clad laminates and polypropylene film used in capacitors. A new feature is the inclusion of capital equipment makers, a category left out in earlier programs. For several items, companies earn higher incentives when they source or produce key materials in India, which encourages backward integration into items like laminates and films. The first approvals reflect these choices, with projects for PCBs and laminates by Kaynes Circuits and Ascent Circuits, camera modules by Kaynes, and polypropylene film by SRF. Syrma Strategic Electronics will add more PCB capacity.

How the incentives work

ECMS offers three paths, a turnover linked incentive, a capex linked incentive, and a hybrid option that blends both. Benefits are spread across the scheme period, and firms must meet measurable thresholds on investment, sales and employment to qualify for each tranche. Part of the payout is tied to job creation. There is an upper cap so total incentive support cannot exceed half of the investment, a design meant to keep projects focused on improving productivity and quality. The policy also pushes conformance with global standards like Six Sigma practices and UL certification to help Indian plants sell into international supply chains without relying on tariff walls. Backward linkages are encouraged, so items such as HDI PCBs or lithium ion materials can receive a higher rate when critical inputs are made locally.

Where the first plants are coming up

Tamil Nadu has emerged as the early hub, winning five of the seven projects. New facilities are planned around Chennai, Thoothukudi and Hosur, close to existing phone and electronics assembly clusters and major ports. Kaynes Circuits will set up plants for multi layer PCBs, HDI PCBs, copper laminates and camera module sub assemblies. Hosur based Ascent Circuits of the Amber Group will add a large PCB line. Syrma Strategic Electronics plans a PCB unit in Andhra Pradesh, while SRF will invest in Madhya Pradesh to make polypropylene film used in capacitors.

The aggregate capex of Rs 5,532 crore includes four projects by Kaynes worth about Rs 3,280 crore, Ascent Circuits at Rs 991 crore and Syrma at Rs 765 crore. SRF will spend roughly Rs 496 crore on polypropylene film, marking its entry into electronic materials. Authorities expect more than 5,100 direct jobs in this batch and have issued approval letters quickly to keep projects on schedule. Incentive payouts begin only after production starts, a feature intended to get factories running fast.

Once operational, these units are expected to meet around 20 percent of India needs for high density PCBs and 15 percent for camera modules. Officials say domestic capacity will meet all of the current requirement for copper clad laminates and polypropylene film. The government has also said about 60 percent of the output from these plants will be exported, giving the new lines a path to scale beyond the domestic market.

Why PCBs, camera modules and laminates matter

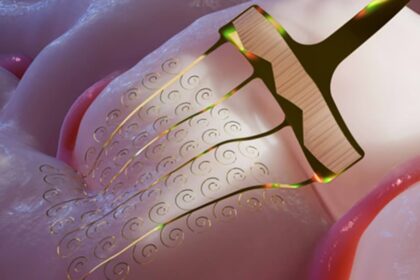

Every modern device sits on a printed circuit board. A PCB holds and connects the chips, memory, power circuits and sensors that make a phone, server, car or aircraft system work. Complex designs like HDI PCBs pack many layers of copper traces into a small area, which requires tight tolerances, clean rooms, expensive equipment and disciplined process control. Without reliable PCB lines, a country that assembles phones or base stations cannot control quality, lead time or the bill of materials.

Copper clad laminates are the base material for PCBs. They combine copper foil and insulating resin on a glass fiber substrate. If laminates are imported, PCB makers face long lead times, currency risk and thickness limits that complicate yield. Building laminate lines alongside PCB plants reduces logistics cost and gives engineers room to co design materials and boards for better performance. Polypropylene film is a thin dielectric used inside capacitors that sit in power supplies for everything from laptops to medical devices and electric vehicles. Localizing this film helps the energy and automotive sectors as well.

Camera modules are highly engineered sub assemblies that combine image sensors, lenses, voice coil motors for autofocus and image processing. They are among the costlier parts in a smartphone bill of materials and they are critical for quality in markets that reward camera performance. Running this line at home reduces import bills and can spark design work in optics, mechatronics and imaging algorithms.

The import gap India wants to close

Component imports reached 36.8 billion dollars in fiscal 2025. Nearly 40 percent were sourced from China, and more than 16 percent came via Hong Kong. This deep reliance exposes Indian manufacturers to changes in export rules, shipping costs and geopolitical pressure. ECMS is, at its core, a risk management move to secure a steady pipeline of inputs for a fast growing electronics sector.

At the same time, India is emerging as a credible base for exports. Electronics exports expanded eight fold in a decade to 38.56 billion dollars. India became the top supplier of smartphones to the United States in the September 2025 quarter as companies diversified production. Global brands that add component lines alongside device assembly can serve domestic demand and export from the same facilities, which improves utilization and cost.

How ECMS ties into the semiconductor and PLI push

The component plan sits alongside earlier policies. Production linked incentives for phones, IT hardware and telecom equipment seek to drive scale in finished goods. The National Policy on Electronics 2019 and the Electronics Manufacturing Clusters program improve land, power and logistics. The Electronics Development Fund supports risk capital for local design companies. The Scheme for Promotion of Manufacturing of Electronic Components and Semiconductors offered a 25 percent capital subsidy for a broad set of parts. ECMS updates the incentive toolkit, refocuses it on priority components and adds a route for capital equipment makers.

On the upstream side, the Semicon India program backs fabs and assembly and test plants. Projects by Micron, Tata Electronics and the HCL Foxconn venture are building packaging, assembly and display capacity. Global component leaders like Murata are expanding footprints in India. Policy makers want design led manufacturing, and India already has a large pool of chip designers. The country produces more than two million STEM graduates every year and bodies like the Electronics Sector Skills Council of India are rolling out targeted training for factory roles.

A realistic goal many officials cite is to lift domestic value addition in electronics to roughly one third within five years. That requires not just more factories but also suppliers of chemicals, gases, laminates and films, and a base of engineers who can design, process and certify products for demanding customers.

Challenges that could slow progress

Raw material depth is a major test. PCB production depends on copper foil, glass fiber cloth, epoxy resins, photoresists and specialty chemicals. Many of these inputs are still imported. A shift to domestic sources will take fresh investment by chemical and materials companies and long qualification cycles. Price swings in copper and energy can pressure margins.

Process know how and yields matter in PCBs and camera modules. HDI lines require precise drilling, laser direct imaging and tight lamination controls. Camera module assembly demands clean environments, optical alignment and robust testing. These are complex operations where early output can carry defects until teams climb the learning curve. Partnerships with global technology providers can accelerate that transition. ECMS signals openness to such tie ups, while rewarding results rather than promises.

Quality systems and certification are another gate. Customers will ask for compliance with international standards, including UL for safety, IPC for PCBs and rigorous reliability testing. Policy makers are steering the sector toward global norms. Some executives worry about hidden barriers in export markets, but the broader message in Delhi is that Indian plants must compete on quality, delivery and cost rather than protection.

Financing is also a factor. PCB and material plants are capital heavy and take time to ramp. Because incentives flow after production starts, firms need working capital to cross the gap between construction and steady state output. States will also have to deliver reliable power, water and waste treatment to keep lines stable. Logistics needs upgrades so components can move quickly to export ports.

Impact on states and jobs

Tamil Nadu is set to benefit from a deeper supply base around its handset and electronics assembly belt near Chennai and Sriperumbudur. Hosur, an hour from Bengaluru, has attracted component makers in automotive and electronics. Andhra Pradesh and Madhya Pradesh will add new nodes away from traditional hubs, balancing growth across regions and tapping new labor pools.

The first seven ECMS projects are expected to create 5,195 direct jobs. The broader program and related schemes aim for more than 90,000 direct roles and large indirect employment in logistics, maintenance and tools. Industry bodies and the Electronics Sector Skills Council are preparing curricula for PCB fabrication, optical assembly and equipment maintenance so local workers can fill these positions.

What to watch next

The first application window for most components closed on September 30, while the window for capital equipment remains open. More approvals are expected in batches before 2027. Letters for the first seven were issued within weeks, and companies say construction timelines are tight because incentive payouts start only after production begins. Watch for early shipments of copper clad laminates and polypropylene film, signs that backward integration is taking hold. Exports from these facilities are expected to account for about 60 percent of output. India is also targeting a greater share of global electronics exports by 2030, potentially reaching 4 to 5 percent if current momentum holds.

The Bottom Line

- Seven ECMS projects worth Rs 5,532 crore received approval under a 2.7 billion dollar component plan.

- New plants will make PCBs, camera modules, copper clad laminates and polypropylene film.

- Five units are in Tamil Nadu, with one each in Andhra Pradesh and Madhya Pradesh.

- Expected coverage includes 20 percent of domestic demand for high density PCBs, 15 percent for camera modules, and full coverage for laminates and polypropylene film.

- About 60 percent of output from these plants is planned for export.

- Electronics exports reached 38.56 billion dollars in FY2025, while component imports were 36.8 billion dollars, with China supplying nearly 40 percent.

- ECMS provides turnover linked, capex linked and hybrid incentives over six years, with a one year setup period and a cap that limits incentives to 50 percent of investment.

- A total of 249 applications have been filed under the scheme, proposing investments of about Rs 1.15 lakh crore.

- The first batch is expected to create 5,195 direct jobs, with many more roles in supporting services.

- ECMS works with PLI and the semiconductor mission to raise domestic value addition toward one third of the electronics value chain within five years.